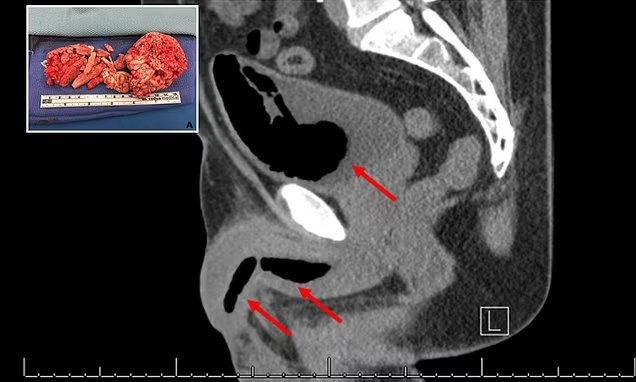

ETH Zurich / Thomas Buchner

ETH Zurich / Thomas BuchnerWhile 3D printers can now build homes, entire robots, skin, and even cheesecakes, they’ve been fairly limited when it comes to the world of soft robotics—which are robots that are made of more flexible yet strong materials. This is primarily due to the fact that much of 3D printing technology relies on fast-curing plastics (also called polyacrylates) that quickly harden once printed.

While this is good for making, say, a set of dice for Dungeons and Dragons or a bottle opener, it’s less ideal for things like creating prosthetic limbs. That’s why an international team of researchers in Switzerland and the U.S. have created a new 3D printing process that allows users to create more elastic materials along with rigid ones using slow-curing polymers.

The team published a paper Wednesday in the journal Nature where they were able to use the system to create a 3D printed hand complete with bones, ligaments, and tendons. The new process also utilizes a laser sensor array developed by researchers at MIT that allows the printer to actually “see” what it’s creating as it creates it.

1 year ago

443

1 year ago

443

English (United States) ·

English (United States) ·